Epoxy connection

Each epoxy coupler product must be tested before packaging:

1. Internal thread detection of go-no-go effect.

2. Check the uniform thickness of the epoxy coating on the surface.

3. Mechanical tensile test.

Epoxy anti-rust connection

Corrosion Protection: Before epoxy coating, the internal threads of the coupler must be protected before

processing.

In order to avoid surface damage and epoxy parts falling off due to collision during transportation and use, all

epoxy couplers produced by our company adopt vacuum heat treatment to allow epoxy to be adsorbed on the

outer wall of the coupler instead of simple paint type of surface coating, which is truly anti-impact, anti-rust and

anti-corrosion epoxy, and has been successfully used in the Qatar seawater desalination project.

Through the test, the facts prove that our epoxy is of high quality.

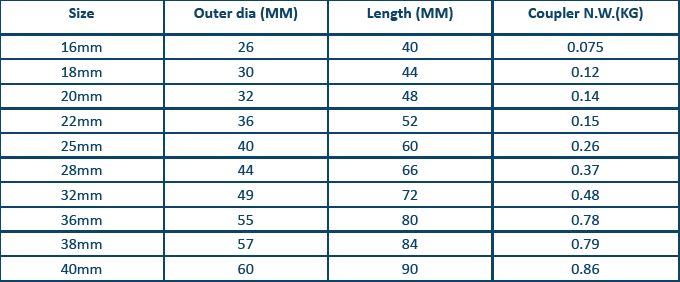

Coupler size table